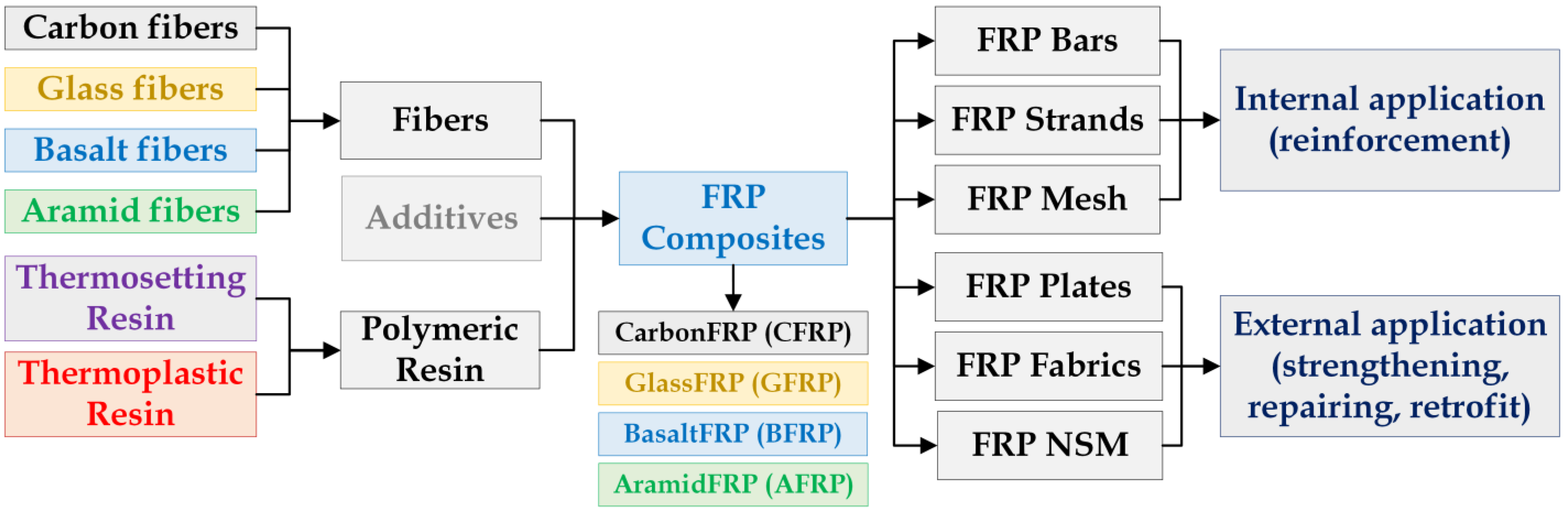

Traditional epoxy resins are indeed a bit more rigid and corrosion-resistant. However, bio-resins have a few other benefits besides biodegradability that make them very attractive for use in the creation of FRP composite products. They are more water-resistant and UV radiation-resistant.Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English fiber) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt.The FRP systems are divided into carbon (CFRP), glass (GFRP), aramid (AFRP), and basalt (BFRP) systems [Triantafyllou 2004]. Carbon fibre reinforced polymers (CFRP). Carbon fibre reinforced polymers have the best mechanical properties amongst other FRP composites, and have the more favourable price to properties ratio.

What are the properties of fiber reinforced polymer : Fiber-reinforced polymer composite offers not only high strength to weight ratio, but also reveals exceptional properties such as high durability; stiffness; damping property; flexural strength; and resistance to corrosion, wear, impact, and fire.

How long will FRP last

20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years. When it comes to structural building materials that last, streel has long held a position at the top of the industry.

How durable is FRP : So… how durable and reliable is FRP, exactly As an easy-to-follow comparison, FRP is stronger and more durable than steel – a material we'd traditionally have used to strengthen and reinforce concrete structures in applications such as `steel jacketing`.

Offering high durability and strength, as well as reliable resistance to corrosion, FRP is long-lasting and mitigates the need for ongoing maintenance. Fiber Reinforced Plastic or Fiberglass Reinforced Plastic (FRP) products are created using high-quality polymer and fibers that enhance the surface's strength and durability.

Is FRP better than plastic

FRP has a higher stiffness, strength and resistance to fatigue. It resists rippling or fracture. FRP is often laminated to metal for increased impact resistance e.g. wide body aircraft. Plastic is perfect for items which are likely to suffer less dynamic stress, like appliance casings.The durability of FRP composites is influenced by factors like moisture absorption, chemical reactions, and microstructural changes, leading to a decline in mechanical strength over time. Moisture and humidity significantly impact FRP composite properties, causing reduced strength and interlayer shear strength.2. FRP composite materials

Property

Material Type

CFRP

GFRP

Density (gm/cm3)

1.50–2.10

1.25–2.50

Tensile Strength (MPa)

600–3920

483–4580

Young's Modulus (GPa)

37–784

35–86

In practice, FRP structural components have been in service for no more than 40 years and have yet to reach the end of their service life. FRP wastes related to the construction industry are mainly those from FRP production and removal of materials on site.

Does FRP break easily : FRP products need little time for production and installation, without compromising durability or function. Highly impact resistant and won't break under impact as traditional materials might. You can get better performance with fewer materials.

What are the weaknesses of FRP : Poor long-term temperature resistance. FRP cannot be used under high temperature for a long time, the strength of polyester FRP decreases obviously when it is above 50℃, and it is generally only used under 100℃. The strength of epoxy FRP decreases obviously above 60℃.

How long does FRP last

20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years. Traditional building materials have their place. But for harsh, corrosive environments, Bedford fiberglass reinforced polymer (FRP) is a smart choice. Bedford structural fiberglass has the strength of steel at a fraction of the weight. It won't corrode, rot, attract insect damage or conduct electricity.However, FRP composites also have disadvantages, such as their relatively high cost, low elastic modulus, linear-elastic brittle behaviour, and poor fire resistance.

How long can FRP last : 20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years. When it comes to structural building materials that last, streel has long held a position at the top of the industry.

Antwort What is the life of FRP material? Weitere Antworten – Is FRP biodegradable

Traditional epoxy resins are indeed a bit more rigid and corrosion-resistant. However, bio-resins have a few other benefits besides biodegradability that make them very attractive for use in the creation of FRP composite products. They are more water-resistant and UV radiation-resistant.Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English fiber) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt.The FRP systems are divided into carbon (CFRP), glass (GFRP), aramid (AFRP), and basalt (BFRP) systems [Triantafyllou 2004]. Carbon fibre reinforced polymers (CFRP). Carbon fibre reinforced polymers have the best mechanical properties amongst other FRP composites, and have the more favourable price to properties ratio.

What are the properties of fiber reinforced polymer : Fiber-reinforced polymer composite offers not only high strength to weight ratio, but also reveals exceptional properties such as high durability; stiffness; damping property; flexural strength; and resistance to corrosion, wear, impact, and fire.

How long will FRP last

20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years. When it comes to structural building materials that last, streel has long held a position at the top of the industry.

How durable is FRP : So… how durable and reliable is FRP, exactly As an easy-to-follow comparison, FRP is stronger and more durable than steel – a material we'd traditionally have used to strengthen and reinforce concrete structures in applications such as `steel jacketing`.

Offering high durability and strength, as well as reliable resistance to corrosion, FRP is long-lasting and mitigates the need for ongoing maintenance.

Fiber Reinforced Plastic or Fiberglass Reinforced Plastic (FRP) products are created using high-quality polymer and fibers that enhance the surface's strength and durability.

Is FRP better than plastic

FRP has a higher stiffness, strength and resistance to fatigue. It resists rippling or fracture. FRP is often laminated to metal for increased impact resistance e.g. wide body aircraft. Plastic is perfect for items which are likely to suffer less dynamic stress, like appliance casings.The durability of FRP composites is influenced by factors like moisture absorption, chemical reactions, and microstructural changes, leading to a decline in mechanical strength over time. Moisture and humidity significantly impact FRP composite properties, causing reduced strength and interlayer shear strength.2. FRP composite materials

In practice, FRP structural components have been in service for no more than 40 years and have yet to reach the end of their service life. FRP wastes related to the construction industry are mainly those from FRP production and removal of materials on site.

Does FRP break easily : FRP products need little time for production and installation, without compromising durability or function. Highly impact resistant and won't break under impact as traditional materials might. You can get better performance with fewer materials.

What are the weaknesses of FRP : Poor long-term temperature resistance. FRP cannot be used under high temperature for a long time, the strength of polyester FRP decreases obviously when it is above 50℃, and it is generally only used under 100℃. The strength of epoxy FRP decreases obviously above 60℃.

How long does FRP last

20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years.

Traditional building materials have their place. But for harsh, corrosive environments, Bedford fiberglass reinforced polymer (FRP) is a smart choice. Bedford structural fiberglass has the strength of steel at a fraction of the weight. It won't corrode, rot, attract insect damage or conduct electricity.However, FRP composites also have disadvantages, such as their relatively high cost, low elastic modulus, linear-elastic brittle behaviour, and poor fire resistance.

How long can FRP last : 20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years. When it comes to structural building materials that last, streel has long held a position at the top of the industry.