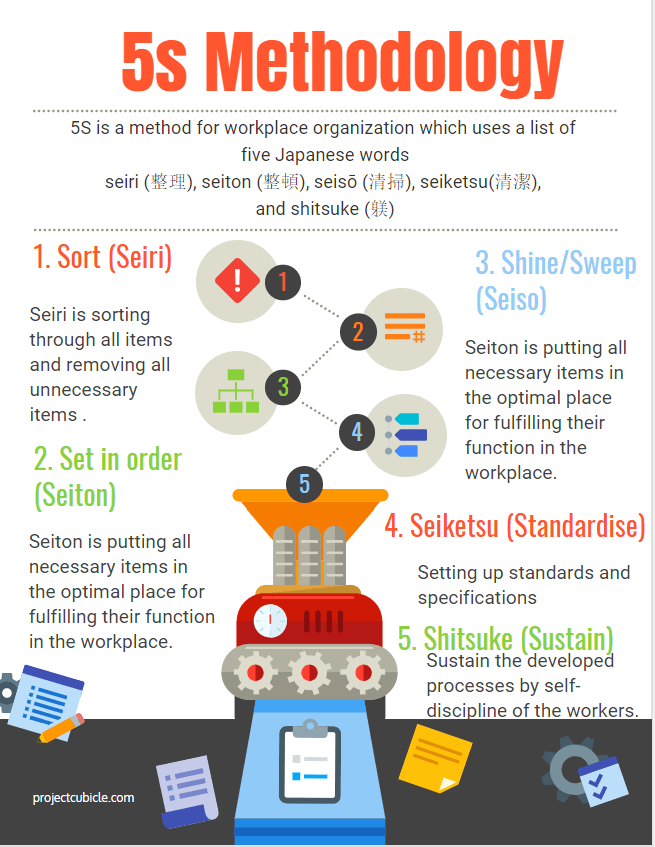

Method and Implementation Approach. 5S is a cyclical methodology: sort, set in order, shine, standardize, sustain the cycle. This results in continuous improvement.5S is a five-step methodology that, when followed, creates a more organized and productive workspace. In English, the 5S's are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.Kaizen 5S framework

A 5S framework is a critical part of the Kaizen system and establishes an ideal physical workplace. The 5Ses focus on creating visual order, organization, cleanliness and standardization to improve profitability, efficiency, service and safety.

What is 5S workplace organization : 5S stands for the 5 steps of this methodology: Sort, Set in Order, Shine, Standardise, Sustain. These steps involve going through everything in a space, deciding what is necessary and what isn't, putting things in order, cleaning, and setting up procedures for performing these tasks on a regular basis.

What is 5S with an example

5s Lean is a systematic approach aimed at optimizing workplace operations by reducing waste, improving efficiency, and creating an organized environment. The methodology derives its name from its core principles: Sort, Set in Order, Shine, Standardize, and Sustain.

Why 5S is used : The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment, both physically and mentally. The five words in 5S represent the five steps to accomplish this goal. They are sort, set, shine, standardize and sustain. Lean bases the words on the original Japanese: seiri, seiton, seiso, seiketsu and shitsuke. 5S is a key component in eliminating the eight wastes of Lean when setting up a workstation.

What is 5S in Kanban

What Are the 5S

Japanese term

Japanese meaning

English equivalent

Seiri

Organize

Sort

Seiton

Orderliness

Set in order, straighten

Seiso

Cleanliness

Shine

Seikutse

Standardize

Standardize

The five words in 5S represent the five steps to accomplish this goal. They are sort, set, shine, standardize and sustain. Lean bases the words on the original Japanese: seiri, seiton, seiso, seiketsu and shitsuke. 5S is a key component in eliminating the eight wastes of Lean when setting up a workstation.5S is designed to decrease waste while optimizing productivity through maintaining an orderly workplace and using visual cues to attain more consistent operational results. 5S refers to five steps – sort, set in order, shine, standardize and sustain (also known as the 5 pillars of a visual workplace). The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

How do you calculate 5S : To find the total 5S audit score, simply divide sum of the audit by 5, the number of “S” standards being evaluated. For example, if you scored each “S” a 3 (perfect score), the total score of the audit will be 3 ((3+3+3+3+3) / 5).

What is the 5S strategy : The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

What is the 5S methodology

The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain. The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.These have been translated as sort, set, shine, standardize and sustain – giving five words beginning with S in English as well. We will take a look at some examples of the ways in which this project management methodology can be used and how this efficient method can be of benefit to project teams.

What is HP 5S methodology : Hewlett-Packard has been using 5S to streamline their daily processes and prevent unnecessary loss of time by systematically arranging workspace items. The company has optimized its storage spaces by organizing storage areas similar to supermarket shelves.

Antwort What is the 5S in agile? Weitere Antworten – What is 5S meaning

Method and Implementation Approach. 5S is a cyclical methodology: sort, set in order, shine, standardize, sustain the cycle. This results in continuous improvement.5S is a five-step methodology that, when followed, creates a more organized and productive workspace. In English, the 5S's are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.Kaizen 5S framework

A 5S framework is a critical part of the Kaizen system and establishes an ideal physical workplace. The 5Ses focus on creating visual order, organization, cleanliness and standardization to improve profitability, efficiency, service and safety.

What is 5S workplace organization : 5S stands for the 5 steps of this methodology: Sort, Set in Order, Shine, Standardise, Sustain. These steps involve going through everything in a space, deciding what is necessary and what isn't, putting things in order, cleaning, and setting up procedures for performing these tasks on a regular basis.

What is 5S with an example

5s Lean is a systematic approach aimed at optimizing workplace operations by reducing waste, improving efficiency, and creating an organized environment. The methodology derives its name from its core principles: Sort, Set in Order, Shine, Standardize, and Sustain.

Why 5S is used : The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment, both physically and mentally.

The five words in 5S represent the five steps to accomplish this goal. They are sort, set, shine, standardize and sustain. Lean bases the words on the original Japanese: seiri, seiton, seiso, seiketsu and shitsuke. 5S is a key component in eliminating the eight wastes of Lean when setting up a workstation.

What is 5S in Kanban

What Are the 5S

The five words in 5S represent the five steps to accomplish this goal. They are sort, set, shine, standardize and sustain. Lean bases the words on the original Japanese: seiri, seiton, seiso, seiketsu and shitsuke. 5S is a key component in eliminating the eight wastes of Lean when setting up a workstation.5S is designed to decrease waste while optimizing productivity through maintaining an orderly workplace and using visual cues to attain more consistent operational results. 5S refers to five steps – sort, set in order, shine, standardize and sustain (also known as the 5 pillars of a visual workplace).

The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

How do you calculate 5S : To find the total 5S audit score, simply divide sum of the audit by 5, the number of “S” standards being evaluated. For example, if you scored each “S” a 3 (perfect score), the total score of the audit will be 3 ((3+3+3+3+3) / 5).

What is the 5S strategy : The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

What is the 5S methodology

The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.These have been translated as sort, set, shine, standardize and sustain – giving five words beginning with S in English as well. We will take a look at some examples of the ways in which this project management methodology can be used and how this efficient method can be of benefit to project teams.

What is HP 5S methodology : Hewlett-Packard has been using 5S to streamline their daily processes and prevent unnecessary loss of time by systematically arranging workspace items. The company has optimized its storage spaces by organizing storage areas similar to supermarket shelves.