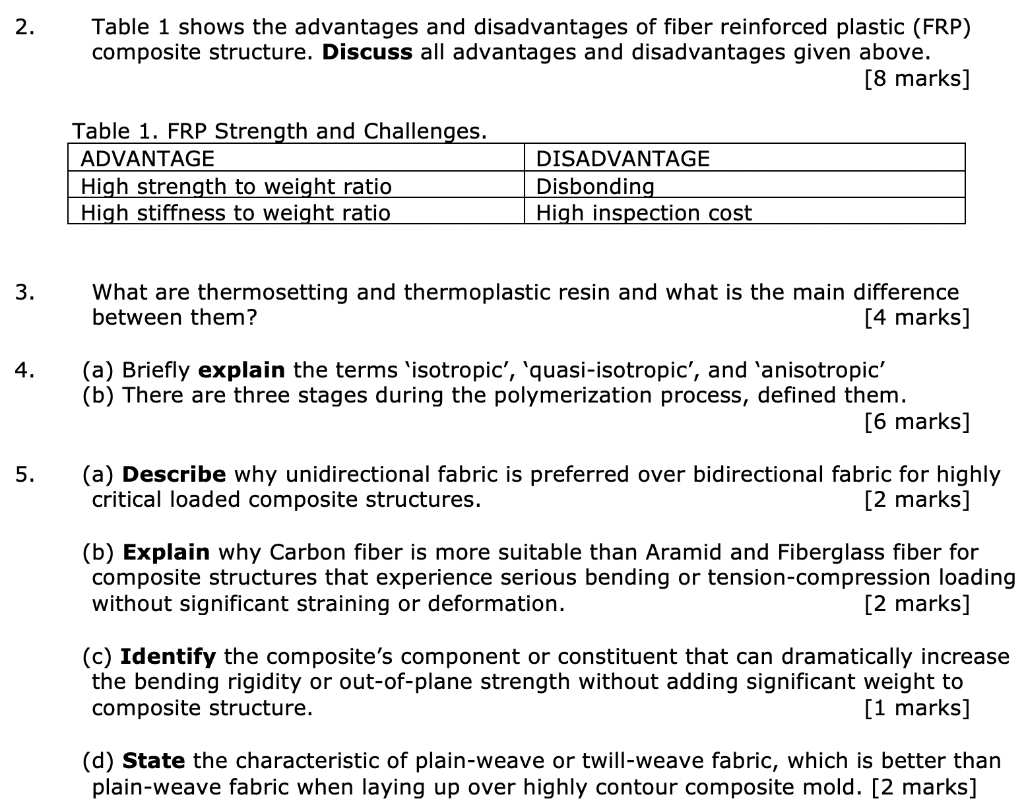

Disadvantages: FRP may lose strength and stiffness at high temperatures, especially when approaching the glass transition temperature of the resin. Advantages of using fibre reinforced polymers (FRP) include high strength and durability. Disadvantages include potential debonding issues.Fibre-reinforced polymer (FRP) , also Fibre-reinforced plastic , is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, or aramid, although other fibres such as paper or wood or asbestos have been sometimes used.Over the years, many industrial owners have complained about the downsides of FRP panels, such as poor insulation, fragility, and constant cracking issues, and much more. The panels have failed to showcase the long-term robustness and insulation, which is a huge disappointment.

What are the disadvantages of Fibre reinforced concrete : What are the disadvantages of using fiber-reinforced concrete

Must be mixed carefully. The fibers used in fiber-reinforced concrete must be dispersed meticulously and uniform throughout the concrete mix.

Cost. Compared to non-reinforced concrete, fiber-reinforced concrete is more expensive.

Weight.

What are the disadvantages of FRP composites

The disadvantages of FRP

Low modulus of elasticity. The modulus of elasticity of FRP is twice as large as that of wood, but 10 times smaller than that of steel (E=2.1*106).

The long-term temperature resistance is poor.

Aging phenomenon.

Low interlaminar shear strength.

Is FRP material good or bad : FRP material is more corrosion-resistant than steel, can withstand a variety of acid, alkali and other environments on its corrosion, good resistance to chemical corrosion.

Plastic typically has a bad reputation when it comes to the environment and suffers from the image of cheap limitation, compared to other materials. But when used correctly, FRP is a good option that is much more sustainable than aluminium, steel or timber. The main failure modes of unidi- rectional plies of fiber-reinforced polymer (FRP) composites are matrix compression failure, matrix tension failure, fiber compression failure, fiber tension failure, delamination.

What are the disadvantages of natural fiber-reinforced composites

On the other hand, it is important to be aware of the cons when using natural fibres, which can include:

Not very durable.

Low density and lightweight.

They have an incompatible nature.

Absorb moisture and water which makes them easily at risk of damage.

The durability of FRP composites is influenced by factors like moisture absorption, chemical reactions, and microstructural changes, leading to a decline in mechanical strength over time. Moisture and humidity significantly impact FRP composite properties, causing reduced strength and interlayer shear strength.For more traditional fire risk scenarios, however, FRP should be considered as a fire hazard that requires fire protection and specific guidance on firefighting measures when the FRP ignites. Poor long-term temperature resistance. FRP cannot be used under high temperature for a long time, the strength of polyester FRP decreases obviously when it is above 50℃, and it is generally only used under 100℃. The strength of epoxy FRP decreases obviously above 60℃.

What are 3 disadvantages of composite materials : Disadvantages of Composite Materials

Manufacturing composites can be expensive.

Repairs may require specialised techniques.

Layers can separate under stress.

Some composites degrade in sunlight.

Some composites are not fire-resistant.

Disposal can be challenging.

Recycling composites can be difficult.

What are the major limitations of FRP as a structural material : However, FRP composites also have disadvantages, such as their relatively high cost, low elastic modulus, linear-elastic brittle behaviour, and poor fire resistance.

What are the disadvantages of fiberglass reinforced plastic

Some of the main disadvantages of GRP include: – Brittleness: GRP can be brittle and prone to cracking or breaking under sudden impact. This can be a concern in applications where the material is exposed to high stress or impact loads. Generally, FRP cannot be used at high temperature for a long time. The strength of universal polyester FRP decreases significantly above 50°C, and generally only used below 100℃; Universal epoxy FRP has a significant decrease in strength above 60℃.Polymer matrix composites have several disadvantages. One major disadvantage is their poor performance when exposed to high heat flux. At temperatures above 300-400°C, the organic matrix decomposes, releasing heat, smoke, and toxic volatiles, which can compromise the mechanical performance of the composite.

What is a disadvantage of carbon fiber composite : Cons: Once the ultimate strength is exceeded, carbon fiber will fail suddenly and catastrophically. Carbon fiber materials are significantly more expensive than traditional materials. Working with carbon fiber requires a high skill level and specialized tooling to produce high-quality structural materials.

Antwort What are the disadvantages of fiber reinforced polymers? Weitere Antworten – What are the advantages and disadvantages of Fibre reinforced polymers

Disadvantages: FRP may lose strength and stiffness at high temperatures, especially when approaching the glass transition temperature of the resin. Advantages of using fibre reinforced polymers (FRP) include high strength and durability. Disadvantages include potential debonding issues.Fibre-reinforced polymer (FRP) , also Fibre-reinforced plastic , is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, or aramid, although other fibres such as paper or wood or asbestos have been sometimes used.Over the years, many industrial owners have complained about the downsides of FRP panels, such as poor insulation, fragility, and constant cracking issues, and much more. The panels have failed to showcase the long-term robustness and insulation, which is a huge disappointment.

What are the disadvantages of Fibre reinforced concrete : What are the disadvantages of using fiber-reinforced concrete

What are the disadvantages of FRP composites

The disadvantages of FRP

Is FRP material good or bad : FRP material is more corrosion-resistant than steel, can withstand a variety of acid, alkali and other environments on its corrosion, good resistance to chemical corrosion.

Plastic typically has a bad reputation when it comes to the environment and suffers from the image of cheap limitation, compared to other materials. But when used correctly, FRP is a good option that is much more sustainable than aluminium, steel or timber.

The main failure modes of unidi- rectional plies of fiber-reinforced polymer (FRP) composites are matrix compression failure, matrix tension failure, fiber compression failure, fiber tension failure, delamination.

What are the disadvantages of natural fiber-reinforced composites

On the other hand, it is important to be aware of the cons when using natural fibres, which can include:

The durability of FRP composites is influenced by factors like moisture absorption, chemical reactions, and microstructural changes, leading to a decline in mechanical strength over time. Moisture and humidity significantly impact FRP composite properties, causing reduced strength and interlayer shear strength.For more traditional fire risk scenarios, however, FRP should be considered as a fire hazard that requires fire protection and specific guidance on firefighting measures when the FRP ignites.

Poor long-term temperature resistance. FRP cannot be used under high temperature for a long time, the strength of polyester FRP decreases obviously when it is above 50℃, and it is generally only used under 100℃. The strength of epoxy FRP decreases obviously above 60℃.

What are 3 disadvantages of composite materials : Disadvantages of Composite Materials

What are the major limitations of FRP as a structural material : However, FRP composites also have disadvantages, such as their relatively high cost, low elastic modulus, linear-elastic brittle behaviour, and poor fire resistance.

What are the disadvantages of fiberglass reinforced plastic

Some of the main disadvantages of GRP include: – Brittleness: GRP can be brittle and prone to cracking or breaking under sudden impact. This can be a concern in applications where the material is exposed to high stress or impact loads.

Generally, FRP cannot be used at high temperature for a long time. The strength of universal polyester FRP decreases significantly above 50°C, and generally only used below 100℃; Universal epoxy FRP has a significant decrease in strength above 60℃.Polymer matrix composites have several disadvantages. One major disadvantage is their poor performance when exposed to high heat flux. At temperatures above 300-400°C, the organic matrix decomposes, releasing heat, smoke, and toxic volatiles, which can compromise the mechanical performance of the composite.

What is a disadvantage of carbon fiber composite : Cons: Once the ultimate strength is exceeded, carbon fiber will fail suddenly and catastrophically. Carbon fiber materials are significantly more expensive than traditional materials. Working with carbon fiber requires a high skill level and specialized tooling to produce high-quality structural materials.