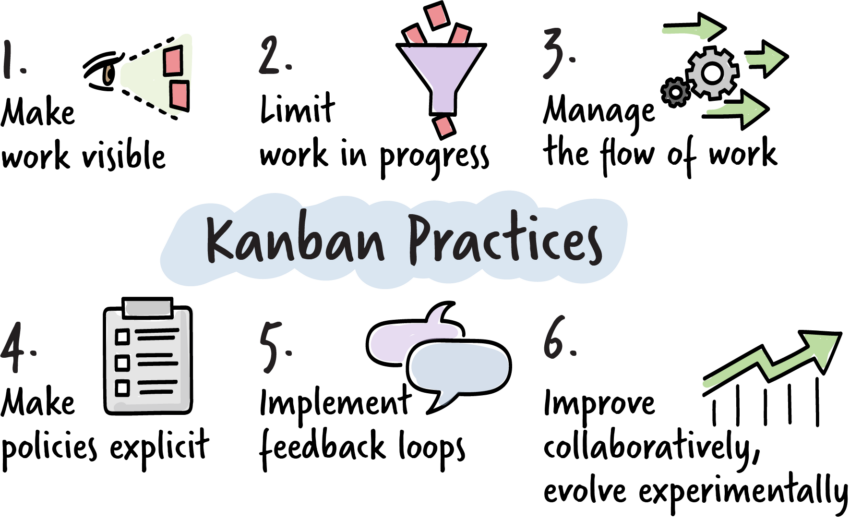

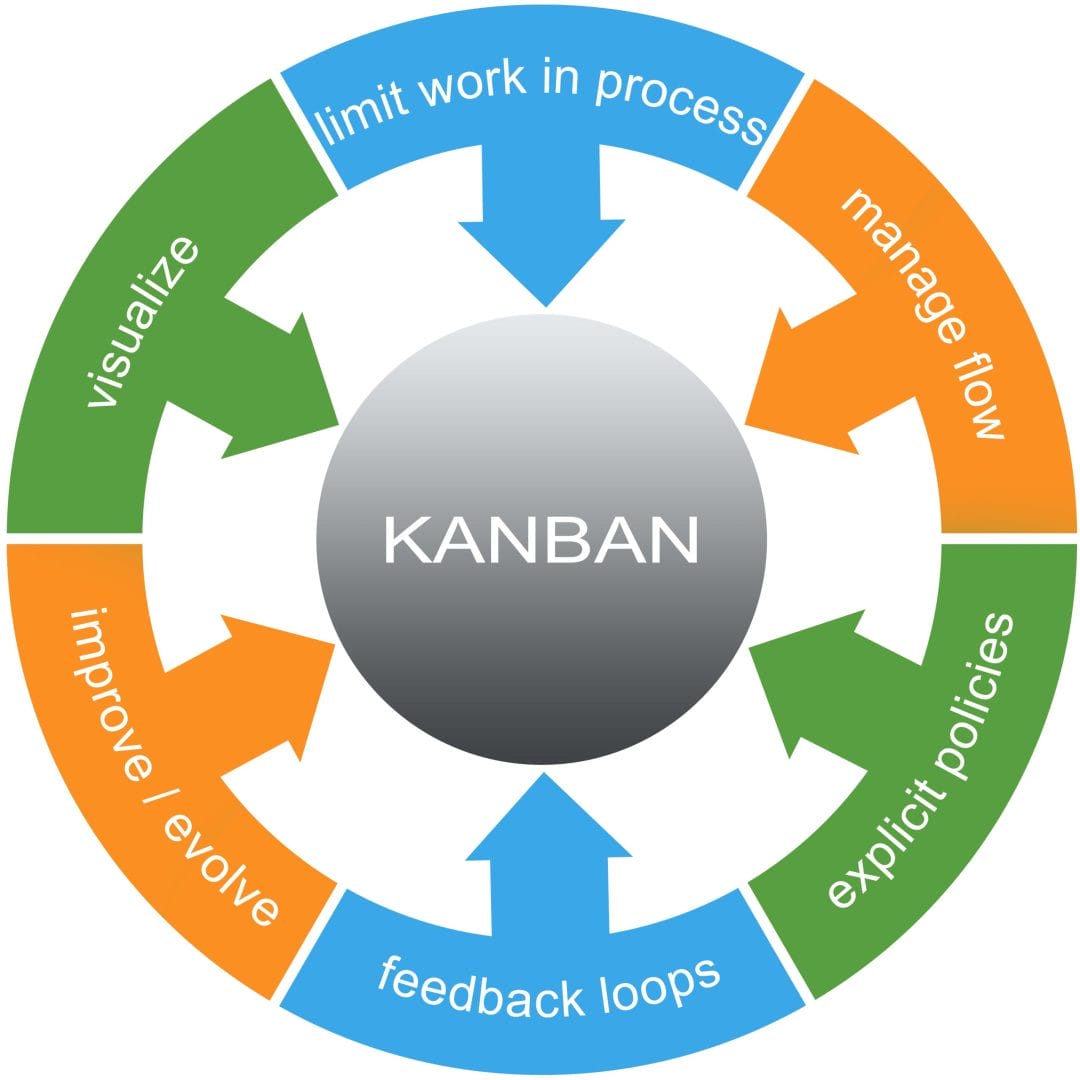

The six foundational Kanban practices for a successful implementation include:

Visualize the workflow.

Limit work in progress.

Manage flow.

Make process policies explicit.

Implement feedback loops.

Improve collaboratively.

No items are made or moved without a Kanban. A Kanban should accompany each item, every time. Defects and incorrect amounts are never sent to the next downstream process. The number of Kanbans is reduced carefully to lower inventories and to reveal problems.The Six Rules of Kanban

Never Pass Defective Products.

Take Only What's Needed.

Produce the Exact Quantity Required.

Level the Production.

Fine-tune the Production or Process Optimization.

Stabilize and Rationalize the Process.

What are the principles of Kanban : There are 4 principles of Kanban, which assist in creating the Kanban Board and help to ensure that the team is always working on the most valuable tasks. They are: Visualize the Work, Limit the Work in Progress (WIP), Focus on Flow, and Continuous Improvement.

How to do Kanban properly

How to create a Kanban Board explained in 5 easy steps:

Step 1: Visualize your workflow.

Step 2: Identify the types of work you do.

Step 3: Write down tasks on cards and place them on the board.

Step 4: Start working with your Kanban board.

Step 5: Improve the flow of work.

What are the three pillars of Kanban : Three pillars uphold every implementation of empirical process control: transparency, inspection, and adaptation.

The main difference is that Kanban uses visualization as the main tool for spotting and eliminating problems, while Lean Six Sigma relies on statistical data and analysis. Additionally, Kanban focuses on the (working) team and is process-oriented. And Lean Six Sigma is customer-focused and process-oriented. Visualize the workflow. The magic of Kanban is the focus on the board. The Kanban agile methodology was inspired by the Toyota Production System.

What is the basic Kanban formula

Kanban number = Demand per unit time * Lead Time (1+Buffer factor)/ Container capacity.Kanban can feel easier than Scrum, because you don't need to follow the strict, prescriptive discipline of Scrum ceremonies. But this freedom also makes it more difficult to do Kanban really well.Kanban Practices

Visualizing the workflow.

Limiting work in progress.

Managing flow.

Making process policies explicit.

Implementing feedback loops.

Improving collaboratively.

The default columns on a Kanban board are Backlog, Selected for Development, In Progress, and Done.

What is a triangle Kanban : Another variant of the kanban system is the triangle kanban. Instead of every part having a kanban card attached, only the last or second-to-last part in the pile has a kanban card attached. This is called a triangle kanban, since the card at Toyota was initially made from metal scrap and triangular.

Is kanban a kaizen tool : In essence, while Kanban gives you the framework for managing your work, Kaizen boards infuse this framework with a spirit of perpetual growth mindset and even with constant small improvements, ensuring that your processes always evolve to meet the changing demands of your projects and team dynamics.

Is kanban Lean or Agile

Kanban is a popular framework used to implement Agile and DevOps software development. It requires real-time communication of capacity and full transparency of work. Work items are represented visually on a kanban board, allowing team members to see the state of every piece of work at any time. 1 The Kanban formula

The formula is: Number of Kanban cards = (Daily demand * Lead time * Safety factor) / Container size Daily demand is the average number of units or parts required per day by the downstream process or customer.How to create a Kanban Board explained in 5 easy steps:

Step 1: Visualize your workflow.

Step 2: Identify the types of work you do.

Step 3: Write down tasks on cards and place them on the board.

Step 4: Start working with your Kanban board.

Step 5: Improve the flow of work.

What is Kanban not good for : Some of the common wrong reasons are:

Varied story sizes – Kanban isn't the answer, the solution is teaching the team to split stories better into small tasks. Inability to finish a story within one iteration – doing Kanban will not impact the speed with which you work in general.

Antwort What are the 6 rules of Kanban? Weitere Antworten – What are the six practices in Kanban

The six foundational Kanban practices for a successful implementation include:

No items are made or moved without a Kanban. A Kanban should accompany each item, every time. Defects and incorrect amounts are never sent to the next downstream process. The number of Kanbans is reduced carefully to lower inventories and to reveal problems.The Six Rules of Kanban

What are the principles of Kanban : There are 4 principles of Kanban, which assist in creating the Kanban Board and help to ensure that the team is always working on the most valuable tasks. They are: Visualize the Work, Limit the Work in Progress (WIP), Focus on Flow, and Continuous Improvement.

How to do Kanban properly

How to create a Kanban Board explained in 5 easy steps:

What are the three pillars of Kanban : Three pillars uphold every implementation of empirical process control: transparency, inspection, and adaptation.

The main difference is that Kanban uses visualization as the main tool for spotting and eliminating problems, while Lean Six Sigma relies on statistical data and analysis. Additionally, Kanban focuses on the (working) team and is process-oriented. And Lean Six Sigma is customer-focused and process-oriented.

Visualize the workflow. The magic of Kanban is the focus on the board. The Kanban agile methodology was inspired by the Toyota Production System.

What is the basic Kanban formula

Kanban number = Demand per unit time * Lead Time (1+Buffer factor)/ Container capacity.Kanban can feel easier than Scrum, because you don't need to follow the strict, prescriptive discipline of Scrum ceremonies. But this freedom also makes it more difficult to do Kanban really well.Kanban Practices

The default columns on a Kanban board are Backlog, Selected for Development, In Progress, and Done.

What is a triangle Kanban : Another variant of the kanban system is the triangle kanban. Instead of every part having a kanban card attached, only the last or second-to-last part in the pile has a kanban card attached. This is called a triangle kanban, since the card at Toyota was initially made from metal scrap and triangular.

Is kanban a kaizen tool : In essence, while Kanban gives you the framework for managing your work, Kaizen boards infuse this framework with a spirit of perpetual growth mindset and even with constant small improvements, ensuring that your processes always evolve to meet the changing demands of your projects and team dynamics.

Is kanban Lean or Agile

Kanban is a popular framework used to implement Agile and DevOps software development. It requires real-time communication of capacity and full transparency of work. Work items are represented visually on a kanban board, allowing team members to see the state of every piece of work at any time.

1 The Kanban formula

The formula is: Number of Kanban cards = (Daily demand * Lead time * Safety factor) / Container size Daily demand is the average number of units or parts required per day by the downstream process or customer.How to create a Kanban Board explained in 5 easy steps:

What is Kanban not good for : Some of the common wrong reasons are:

Varied story sizes – Kanban isn't the answer, the solution is teaching the team to split stories better into small tasks. Inability to finish a story within one iteration – doing Kanban will not impact the speed with which you work in general.