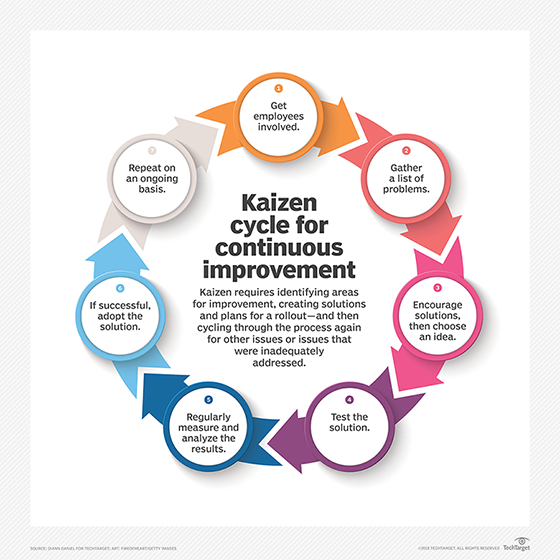

Kaizen is as simple as it is effective. It can be boiled down to a four-step process that can be applied to any project and then applied within the same environment for further improvement. It can also be used across multiple projects at once by deploying four steps called PDCA – or, Plan, Do, Check, Act.The basic steps for implementing a kaizen "event" are outlined below, although organizations typically adapt and sequence these activities to work effectively in their unique circumstances. Phase 1: Planning and Preparation. The first challenge is to identify an appropriate target area for a rapid improvement event.Kaizen, or continuous improvement, in 5 key principles

Kaizen Attitude.

PDCA Cycle (Plan, Do, Check, Act)

Systemization and Systemic Approach.

The Necessity of Continuous Learning.

Implementing Continuous Improvement for Operational Excellence Enterprise-Wide.

What are 5 in Kaizen : Edwards Deming, Kaizen emphasizes making incremental improvements in quality, efficiency, and waste reduction. The 5S methodology, an integral part of Kaizen, consists of Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

What are the 5S of Kaizen

The 5S in Kaizen are Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

What are the 3 C’s of Kaizen : The 3C methodology (Case, Cause, and Countermeasure) is used for more straightforward issues, while for more complex problems, Kobetsu KAIZEN™ is applied.

The 3 principles of Kaizen are: gemba: the place where work is done. gembutsu: the actual product. genjitsu: the facts. 5S is typically defined as a system for creating a clean, organized workspace that makes it easy to identify abnormalities and waste so that employees can do their jobs efficiently, effectively, and without the risk of injury. The 5S method offers a framework for building a visual management process.

Is Kaizen part of 5S

5S is derived from the philosophy of "kaizen", which simply means "continuous improvement". Japanese automotive manufacturer, Toyota, states that the philosophy of "kaizen" is one of its core values. This philosophy is supported by three key principles, one of which is 5S.6S lean manufacturing combines the five key tenants of 5S — sort, straighten, shine, standardize, and sustain — with safety. The goal of 6S is to ensure that safety is a part of all lean manufacturing processes from end to end, in turn reducing the risk of accidents and limiting the amount of production downtime.Kaizen is a Japanese business philosophy that focuses on gradually improving productivity and making a work environment more efficient. Kaizen supports change from any employee at any time. Kaizen translates to change for the better or continuous improvement. There are five principles that kaizen follows, including (1) Know your customer, (2) Let it flow, (3) Go to Gemba, (4)Empower people, and (5) Be transparent. The implementation of kaizen in the workplace has borne many other strategies that helped the productivity of the company.

What are the 5S principles of Kaizen : The five steps are as follows:

Seiri – sort.

Seiton – straighten/ set in order.

Seiso – shine.

Seiketsu – standardise.

Shitsuke – sustain.

What are the 5S pillars of Kaizen : The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.

What are the 5S Kaizen model

Edwards Deming, Kaizen emphasizes making incremental improvements in quality, efficiency, and waste reduction. The 5S methodology, an integral part of Kaizen, consists of Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). Kaizen in relation to Lean Six Sigma

In both cases, this is about the reduction of squandering and variation. Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization.The three pillars of Kaizen include housekeeping, waste elimination, and standardization. At the core of the practice is continuous improvement. Let's now see some of the fundamental principles that lie at the heart of Kaizen. Kaizen's tools are actually the methods and techniques that can reduce waste in processes.

What is the core of Kaizen : The core philosophy behind Kaizen is simple: you can always make or do things better, even if they seem to work well in a particular moment. Furthermore, all problems should be seen as opportunities to improve.

Antwort What are the 4 Ps of Kaizen? Weitere Antworten – What are the four steps of Kaizen

Kaizen is as simple as it is effective. It can be boiled down to a four-step process that can be applied to any project and then applied within the same environment for further improvement. It can also be used across multiple projects at once by deploying four steps called PDCA – or, Plan, Do, Check, Act.The basic steps for implementing a kaizen "event" are outlined below, although organizations typically adapt and sequence these activities to work effectively in their unique circumstances. Phase 1: Planning and Preparation. The first challenge is to identify an appropriate target area for a rapid improvement event.Kaizen, or continuous improvement, in 5 key principles

What are 5 in Kaizen : Edwards Deming, Kaizen emphasizes making incremental improvements in quality, efficiency, and waste reduction. The 5S methodology, an integral part of Kaizen, consists of Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

What are the 5S of Kaizen

The 5S in Kaizen are Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

What are the 3 C’s of Kaizen : The 3C methodology (Case, Cause, and Countermeasure) is used for more straightforward issues, while for more complex problems, Kobetsu KAIZEN™ is applied.

The 3 principles of Kaizen are: gemba: the place where work is done. gembutsu: the actual product. genjitsu: the facts.

5S is typically defined as a system for creating a clean, organized workspace that makes it easy to identify abnormalities and waste so that employees can do their jobs efficiently, effectively, and without the risk of injury. The 5S method offers a framework for building a visual management process.

Is Kaizen part of 5S

5S is derived from the philosophy of "kaizen", which simply means "continuous improvement". Japanese automotive manufacturer, Toyota, states that the philosophy of "kaizen" is one of its core values. This philosophy is supported by three key principles, one of which is 5S.6S lean manufacturing combines the five key tenants of 5S — sort, straighten, shine, standardize, and sustain — with safety. The goal of 6S is to ensure that safety is a part of all lean manufacturing processes from end to end, in turn reducing the risk of accidents and limiting the amount of production downtime.Kaizen is a Japanese business philosophy that focuses on gradually improving productivity and making a work environment more efficient. Kaizen supports change from any employee at any time. Kaizen translates to change for the better or continuous improvement.

There are five principles that kaizen follows, including (1) Know your customer, (2) Let it flow, (3) Go to Gemba, (4)Empower people, and (5) Be transparent. The implementation of kaizen in the workplace has borne many other strategies that helped the productivity of the company.

What are the 5S principles of Kaizen : The five steps are as follows:

What are the 5S pillars of Kaizen : The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.

What are the 5S Kaizen model

Edwards Deming, Kaizen emphasizes making incremental improvements in quality, efficiency, and waste reduction. The 5S methodology, an integral part of Kaizen, consists of Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

Kaizen in relation to Lean Six Sigma

In both cases, this is about the reduction of squandering and variation. Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization.The three pillars of Kaizen include housekeeping, waste elimination, and standardization. At the core of the practice is continuous improvement. Let's now see some of the fundamental principles that lie at the heart of Kaizen. Kaizen's tools are actually the methods and techniques that can reduce waste in processes.

What is the core of Kaizen : The core philosophy behind Kaizen is simple: you can always make or do things better, even if they seem to work well in a particular moment. Furthermore, all problems should be seen as opportunities to improve.