Improve – The principles of kaizen are split into four categories: process, product, people, and environment. Processes : prefect processes by implementing kaizen in all areas of the company. Repeat – Repeat the process. Consistently making improvements is the key to success.Kaizen Teian: Bottom-Up Improvement

Defects: Scrap or products that require rework.

Excess processing: Products that must be repaired to satisfy customers needs.

Overproduction: When there are more parts in production than customers are purchasing.

Waiting: A person or process inaction on the manufacturing line.

Kaizen is a Japanese business philosophy that focuses on gradually improving productivity and making a work environment more efficient. Kaizen supports change from any employee at any time. Kaizen translates to change for the better or continuous improvement.

What is the core of kaizen : The core philosophy behind Kaizen is simple: you can always make or do things better, even if they seem to work well in a particular moment. Furthermore, all problems should be seen as opportunities to improve.

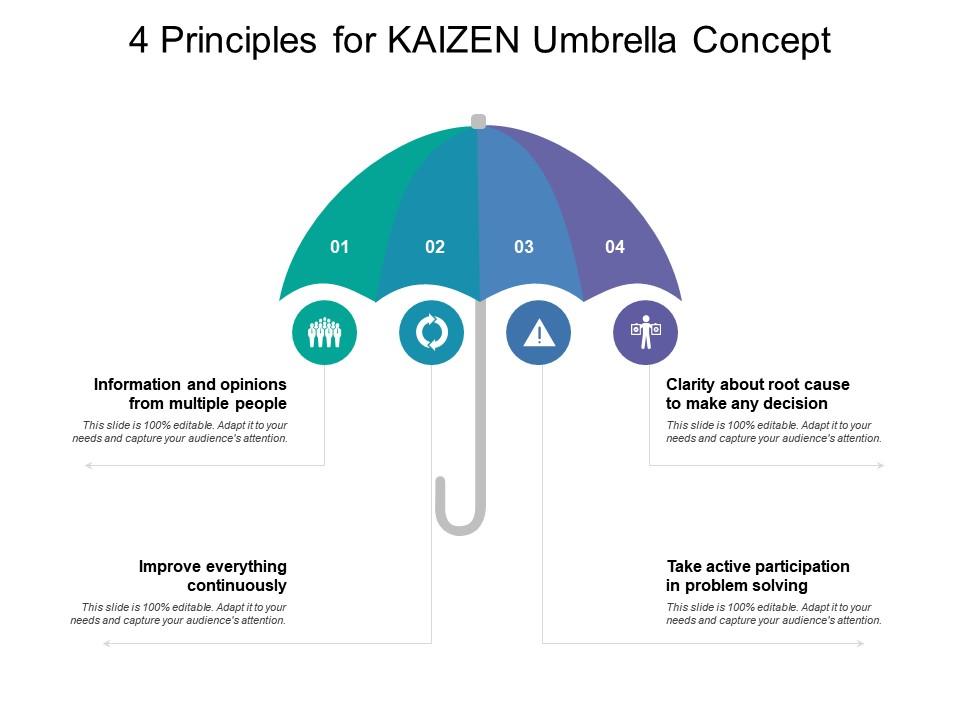

What are the 4 steps of Kaizen

A Kaizen event has four key phases: Selecting, Planning, Implementing and Follow Up.

What are the 5 Kaizen principles : There are five principles that kaizen follows, including (1) Know your customer, (2) Let it flow, (3) Go to Gemba, (4)Empower people, and (5) Be transparent. The implementation of kaizen in the workplace has borne many other strategies that helped the productivity of the company.

Edwards Deming, Kaizen emphasizes making incremental improvements in quality, efficiency, and waste reduction. The 5S methodology, an integral part of Kaizen, consists of Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). Kaizen is a perfect tool for the second approach, because it's all about the small things you do today rather than making grand plans for someday. Oppong argues for a simple, Kaizen-based approach to self-improvement: Aim for 1 percent improvement today, another 1 percent tomorrow, and so on.

What is the golden rule for Kaizen

Kaizen starts with the three “actual” rule. Go to the actual place where the process is performed. Talk to the actual people involved in the process and get the real facts. Observe and chart the actual process.10 The organizational hierarchy of the "Toyota Way" has been described by Liker as a pyramid of 4 key components, namely Philosophy, Process, People/Partners, and Problem Solving, with an emphasis on continuous improvement (Kaizen or good change) (Fig.There are five 5S phases. They can be translated to English as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. Other translations are possible. Kaizen in relation to Lean Six Sigma

In both cases, this is about the reduction of squandering and variation. Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization.

Is 5S Lean or Six Sigma : Lean Six Sigma

The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.

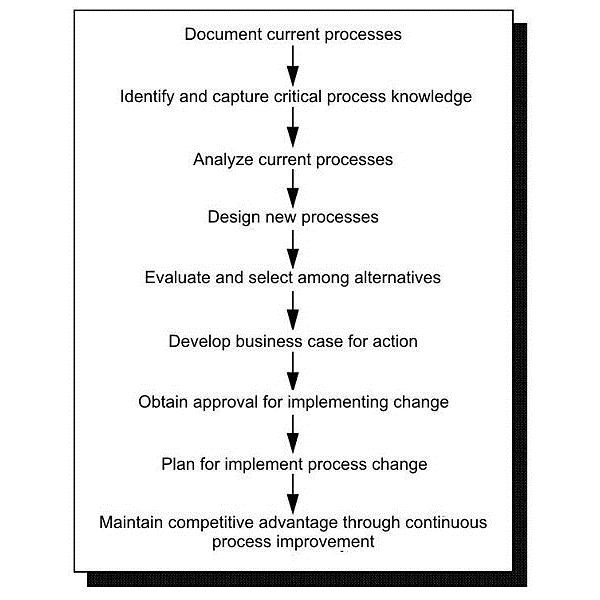

What is the formula for Kaizen : Kaizen tools are simply the methods and techniques used to identify and eliminate waste in a process. What is the formula for Kaizen The cycle of kaizen activity can be defined as: Plan → Do → Check → Act. This is also known as the Shewhart cycle, Deming cycle, or PDCA.

What is the 80 20 rule in Kaizen

It states that 80% of outcomes come from 20% of cases, implying unequal relationships between inputs and outputs. Adhering to this principle means prioritizing business goals and tasks to get maximum results. Learn more about our Six Sigma training. The Kaizen Approach

Brainstorm/Standardize: With a cross-functional team, think of ways to make straightforward, repeatable processes that will improve specific activities.

Measure: Ensure processes are efficient using quantifiable data.

Compare: Compare the data from your measurements with your determined requirements.

While 5S and Kaizen are two distinct philosophies, they are closely related. 5S provides a foundation for Kaizen by creating a workplace environment that is conducive to continuous improvement. Kaizen, in turn, helps to sustain 5S gains by ensuring that the workplace remains organized and efficient over time.

What is 5S in Kaizen : The 5S in Kaizen are Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

Antwort What are the 4 main Kaizen principles? Weitere Antworten – What are the four principles of kaizen

Improve – The principles of kaizen are split into four categories: process, product, people, and environment. Processes : prefect processes by implementing kaizen in all areas of the company. Repeat – Repeat the process. Consistently making improvements is the key to success.Kaizen Teian: Bottom-Up Improvement

Kaizen is a Japanese business philosophy that focuses on gradually improving productivity and making a work environment more efficient. Kaizen supports change from any employee at any time. Kaizen translates to change for the better or continuous improvement.

What is the core of kaizen : The core philosophy behind Kaizen is simple: you can always make or do things better, even if they seem to work well in a particular moment. Furthermore, all problems should be seen as opportunities to improve.

What are the 4 steps of Kaizen

A Kaizen event has four key phases: Selecting, Planning, Implementing and Follow Up.

What are the 5 Kaizen principles : There are five principles that kaizen follows, including (1) Know your customer, (2) Let it flow, (3) Go to Gemba, (4)Empower people, and (5) Be transparent. The implementation of kaizen in the workplace has borne many other strategies that helped the productivity of the company.

Edwards Deming, Kaizen emphasizes making incremental improvements in quality, efficiency, and waste reduction. The 5S methodology, an integral part of Kaizen, consists of Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

Kaizen is a perfect tool for the second approach, because it's all about the small things you do today rather than making grand plans for someday. Oppong argues for a simple, Kaizen-based approach to self-improvement: Aim for 1 percent improvement today, another 1 percent tomorrow, and so on.

What is the golden rule for Kaizen

Kaizen starts with the three “actual” rule. Go to the actual place where the process is performed. Talk to the actual people involved in the process and get the real facts. Observe and chart the actual process.10 The organizational hierarchy of the "Toyota Way" has been described by Liker as a pyramid of 4 key components, namely Philosophy, Process, People/Partners, and Problem Solving, with an emphasis on continuous improvement (Kaizen or good change) (Fig.There are five 5S phases. They can be translated to English as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. Other translations are possible.

Kaizen in relation to Lean Six Sigma

In both cases, this is about the reduction of squandering and variation. Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization.

Is 5S Lean or Six Sigma : Lean Six Sigma

The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.

What is the formula for Kaizen : Kaizen tools are simply the methods and techniques used to identify and eliminate waste in a process. What is the formula for Kaizen The cycle of kaizen activity can be defined as: Plan → Do → Check → Act. This is also known as the Shewhart cycle, Deming cycle, or PDCA.

What is the 80 20 rule in Kaizen

It states that 80% of outcomes come from 20% of cases, implying unequal relationships between inputs and outputs. Adhering to this principle means prioritizing business goals and tasks to get maximum results. Learn more about our Six Sigma training.

The Kaizen Approach

While 5S and Kaizen are two distinct philosophies, they are closely related. 5S provides a foundation for Kaizen by creating a workplace environment that is conducive to continuous improvement. Kaizen, in turn, helps to sustain 5S gains by ensuring that the workplace remains organized and efficient over time.

What is 5S in Kaizen : The 5S in Kaizen are Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).