The 3 principles of Kaizen are: gemba: the place where work is done. gembutsu: the actual product. genjitsu: the facts.The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.The lean concept of 3S stands for three Japanese terms translated into english meaning: sort, sweep, and standardize. It's a simple yet powerful method for creating organization and productivity while identifying problems and “fixing the things that bug us.”

What are the 4 Ps of Kaizen : 10 The organizational hierarchy of the "Toyota Way" has been described by Liker as a pyramid of 4 key components, namely Philosophy, Process, People/Partners, and Problem Solving, with an emphasis on continuous improvement (Kaizen or good change) (Fig.

What is 3S kaizen

The lean concept of 3S stands for three Japanese terms translated into english meaning: sort, sweep, and standardize. It's a simple yet powerful method for creating organization and productivity while identifying problems and “fixing the things that bug us.”

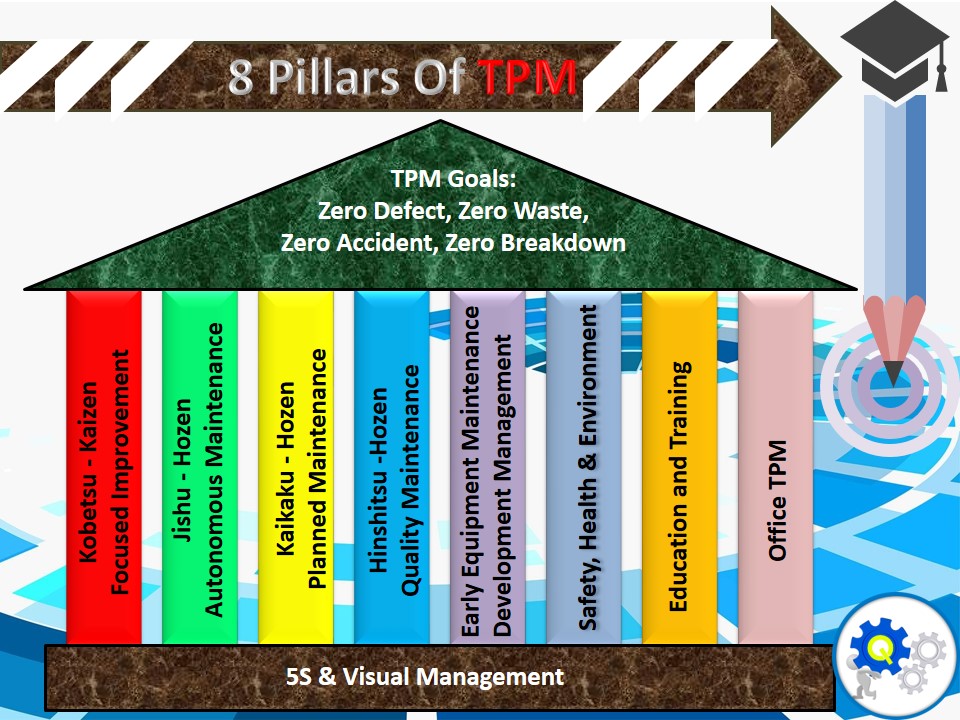

What are the 8 pillars of kaizen : The eight pillars are: autonomous maintenance; focused improvement (kaizen); planned maintenance; quality management; early equipment management; training and education; safety, health and environment; and TPM in administration. Let's break down each pillar below.

6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety. 4M means four factors of production, and it came from the initial letters of the following four factors, Man (workers and operators), Machine (machine and equipment), Material (materials and parts), and Method (method and process).

What is the core of Kaizen

The core philosophy behind Kaizen is simple: you can always make or do things better, even if they seem to work well in a particular moment. Furthermore, all problems should be seen as opportunities to improve.The Lean 7S is the latest methodology which comprises of the seven phases namely Sort, set in order, Shine, Standardize, Sustain or Self Discipline, Safety and Spirit (team Spirit).Kaizen tries to improve the business as a whole by creating a standard way of working, increasing efficiency and eliminating business waste. Six Sigma is more focused on quality output (the final product). This is facilitated through finding and eliminating the causes of defects. 3C and 5S are management tools used in business for process improvement and quality control. 3C stands for three key elements of a process: customer, company, and competition. 5S is a workplace organiza… see more.

How to calculate Kaizen : A typical Kaizen event has a process that goes something like this:

Set goals and provide any necessary background.

Review the current state and develop a plan for improvements.

Implement improvements.

Review and fix what doesn't work.

Report results and determine any follow-up items.

What is 4M Six Sigma : 4M Affinity Diagram: 4M stands for Man, Method, Machine, and Material. The thought behind 4M is that every problem we encounter will fall into one of these categories. 4M begins as a brainstorming session with you and your team.

Is Kaizen lean or six sigma

Kaizen in relation to Lean Six Sigma

In both cases, this is about the reduction of squandering and variation. Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization. Kaizen tries to improve the business as a whole by creating a standard way of working, increasing efficiency and eliminating business waste. Six Sigma is more focused on quality output (the final product). This is facilitated through finding and eliminating the causes of defects.Kaizen DMAIC

Kaizen events may stand alone or be incorporated into an LSS project incorporating the DMAIC approach. Kaizen events may come at any stage of the LSS project. However, they are generally performed at the improvement stage. They may or may not be directly related to the overall LSS project goal.

Is Kaizen Agile or Lean : Derived from the Japanese term for continuous improvement, Kaizen, the agile software development methodology, encapsulates a key principle of Japanese management. Its purpose is to help companies address challenges by identifying areas where commitments fall short and stimulating team brainstorming for enhancements.

Antwort What are the 3 pillars of Kaizen? Weitere Antworten – What are the three basic principles of Kaizen

The 3 principles of Kaizen are: gemba: the place where work is done. gembutsu: the actual product. genjitsu: the facts.The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.The lean concept of 3S stands for three Japanese terms translated into english meaning: sort, sweep, and standardize. It's a simple yet powerful method for creating organization and productivity while identifying problems and “fixing the things that bug us.”

What are the 4 Ps of Kaizen : 10 The organizational hierarchy of the "Toyota Way" has been described by Liker as a pyramid of 4 key components, namely Philosophy, Process, People/Partners, and Problem Solving, with an emphasis on continuous improvement (Kaizen or good change) (Fig.

What is 3S kaizen

The lean concept of 3S stands for three Japanese terms translated into english meaning: sort, sweep, and standardize. It's a simple yet powerful method for creating organization and productivity while identifying problems and “fixing the things that bug us.”

What are the 8 pillars of kaizen : The eight pillars are: autonomous maintenance; focused improvement (kaizen); planned maintenance; quality management; early equipment management; training and education; safety, health and environment; and TPM in administration. Let's break down each pillar below.

6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety.

4M means four factors of production, and it came from the initial letters of the following four factors, Man (workers and operators), Machine (machine and equipment), Material (materials and parts), and Method (method and process).

What is the core of Kaizen

The core philosophy behind Kaizen is simple: you can always make or do things better, even if they seem to work well in a particular moment. Furthermore, all problems should be seen as opportunities to improve.The Lean 7S is the latest methodology which comprises of the seven phases namely Sort, set in order, Shine, Standardize, Sustain or Self Discipline, Safety and Spirit (team Spirit).Kaizen tries to improve the business as a whole by creating a standard way of working, increasing efficiency and eliminating business waste. Six Sigma is more focused on quality output (the final product). This is facilitated through finding and eliminating the causes of defects.

3C and 5S are management tools used in business for process improvement and quality control. 3C stands for three key elements of a process: customer, company, and competition. 5S is a workplace organiza… see more.

How to calculate Kaizen : A typical Kaizen event has a process that goes something like this:

What is 4M Six Sigma : 4M Affinity Diagram: 4M stands for Man, Method, Machine, and Material. The thought behind 4M is that every problem we encounter will fall into one of these categories. 4M begins as a brainstorming session with you and your team.

Is Kaizen lean or six sigma

Kaizen in relation to Lean Six Sigma

In both cases, this is about the reduction of squandering and variation. Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization.

Kaizen tries to improve the business as a whole by creating a standard way of working, increasing efficiency and eliminating business waste. Six Sigma is more focused on quality output (the final product). This is facilitated through finding and eliminating the causes of defects.Kaizen DMAIC

Kaizen events may stand alone or be incorporated into an LSS project incorporating the DMAIC approach. Kaizen events may come at any stage of the LSS project. However, they are generally performed at the improvement stage. They may or may not be directly related to the overall LSS project goal.

Is Kaizen Agile or Lean : Derived from the Japanese term for continuous improvement, Kaizen, the agile software development methodology, encapsulates a key principle of Japanese management. Its purpose is to help companies address challenges by identifying areas where commitments fall short and stimulating team brainstorming for enhancements.