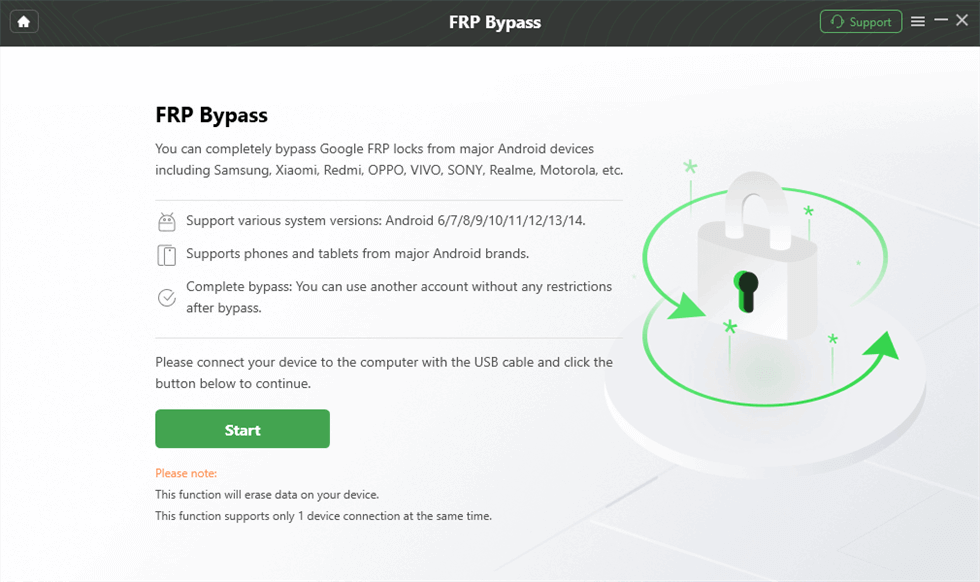

FRP (Factory Reset Prevention) is a security feature in Android designed to restrict people from using your Android device if they forcefully perform an untrusted factory reset on the device. Untrusted factory reset is performed via recovery mode. RFP is a way to prevent theft.Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English fiber) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt.It can be achieved through several processes, including compression molding, bladder molding, wet layup, mandrel molding, chopper gun, autoclave and vacuum bag, filament winding, and pultrusion. We are going to focus on pultrusion, which is arguably the most popular method of FRP production at the moment.

What is FRP reinforcement : Fiber-reinforced polymer (FRP) systems are simply defined as high-strength and lightweight reinforcements created by combining carbon (CFRP) or E-glass fibers with a polymer material.

How do you bond FRP to FRP

Cyanoacrylate – also known as instant adhesives, super glue, crazy glue, ca glue, etc. For bonding FRP fiber reinforced polymer consider a black, toughened grade such as 735 low viscosity or 737 medium viscosity. Note Permabond 731 is a clear, toughened grade. Often FRP can have a very rough surface.

How are fiber reinforced composites manufactured : Some of the commonly used manufacturing techniques of natural fiber reinforced composites are hand layup technique, a compression molding technique, vacuum-assisted resin transfer molding technique, injection molding technique and pultrusion technique.

Cyanoacrylate – also known as instant adhesives, super glue, crazy glue, ca glue, etc. For bonding FRP fiber reinforced polymer consider a black, toughened grade such as 735 low viscosity or 737 medium viscosity. Note Permabond 731 is a clear, toughened grade. Often FRP can have a very rough surface. FRP is made by combining two or more materials to form a composite with superior properties to the individual components. The manufacturing process of FRP involves several steps that require precise control and attention to detail.

What is FRP in cable

Fiberglass cable trays are also referred to as fiberglass reinforced plastic (FRP) cable trays, non-metallic cable trays, and glass-reinforced plastic (GRP) cable trays.Epoxy Adhesives: Known for their high strength and chemical resistance, epoxies are ideal for the structural bonding of FRP panels.Generally, FRP panels can be installed using adhesive alone, fasteners alone, or a combination of adhesive and fasteners. Here's an overview of the common FRP manufacturing processes:

Fiber Selection: The choice of fiber reinforcement is crucial.

Resin Selection: The polymer matrix is typically made from thermosetting or thermoplastic resins.

Prepreg Fabrication:

Layup:

Vacuum Bagging:

Curing:

Trimming and Shaping:

Surface Finish:

What is an FRP composite material How are they manufactured : Manufacturing of FRP composite involves manufacturing of fiber preforms and then reinforcing these fibers with the matrix material by various techniques. Fiber preforms involve weaving, knitting, braiding, and stitching of fibers in long sheets or mat structure [125,126,127].

How to join FRP sheet : Install the Corner Moulding and Panel

Before you start your FRP panels installation, cut your corner moulding.

Use a trowel and apply a 1/4-inch thick layer of FRP adhesive to the back side of the first panel.

Insert the panel into the corner moulding.

Why is FRP used in fiber cable

FRP rods serve a dual purpose. It provides cable reinforcement during installation, reduces tension on signal carrying optic fiber/ conductor. The lightweight FRP prevents the cable from sagging in aerial installations and its rigidity and strength takes on the load of cable. Additionally, FRP is nonconductive, with high dielectric capability, and a good insulator with low thermal conductivity. Pound for pound, FRP is often stronger than steel in the lengthwise direction, but it's important to consider the numbers.Do not bond two non-porous substrates together such as FRP, metal, plastic, foam board, sealed concrete, fiberglass face or mold resistant gypsum wallboard or any other non-porous surfaces. For installations bonding two non-porous substrates together use Titebond Advanced Polymer Panel Adhesive.

Does FRP crack easily : FRPs are brittle, so cracks usually appear in the area where stress is concentrated, such as bolt holes and corner joints of the profile.

Antwort How is FRP connected? Weitere Antworten – How does the FRP work

FRP (Factory Reset Prevention) is a security feature in Android designed to restrict people from using your Android device if they forcefully perform an untrusted factory reset on the device. Untrusted factory reset is performed via recovery mode. RFP is a way to prevent theft.Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English fiber) is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt.It can be achieved through several processes, including compression molding, bladder molding, wet layup, mandrel molding, chopper gun, autoclave and vacuum bag, filament winding, and pultrusion. We are going to focus on pultrusion, which is arguably the most popular method of FRP production at the moment.

What is FRP reinforcement : Fiber-reinforced polymer (FRP) systems are simply defined as high-strength and lightweight reinforcements created by combining carbon (CFRP) or E-glass fibers with a polymer material.

How do you bond FRP to FRP

Cyanoacrylate – also known as instant adhesives, super glue, crazy glue, ca glue, etc. For bonding FRP fiber reinforced polymer consider a black, toughened grade such as 735 low viscosity or 737 medium viscosity. Note Permabond 731 is a clear, toughened grade. Often FRP can have a very rough surface.

How are fiber reinforced composites manufactured : Some of the commonly used manufacturing techniques of natural fiber reinforced composites are hand layup technique, a compression molding technique, vacuum-assisted resin transfer molding technique, injection molding technique and pultrusion technique.

Cyanoacrylate – also known as instant adhesives, super glue, crazy glue, ca glue, etc. For bonding FRP fiber reinforced polymer consider a black, toughened grade such as 735 low viscosity or 737 medium viscosity. Note Permabond 731 is a clear, toughened grade. Often FRP can have a very rough surface.

FRP is made by combining two or more materials to form a composite with superior properties to the individual components. The manufacturing process of FRP involves several steps that require precise control and attention to detail.

What is FRP in cable

Fiberglass cable trays are also referred to as fiberglass reinforced plastic (FRP) cable trays, non-metallic cable trays, and glass-reinforced plastic (GRP) cable trays.Epoxy Adhesives: Known for their high strength and chemical resistance, epoxies are ideal for the structural bonding of FRP panels.Generally, FRP panels can be installed using adhesive alone, fasteners alone, or a combination of adhesive and fasteners.

Here's an overview of the common FRP manufacturing processes:

What is an FRP composite material How are they manufactured : Manufacturing of FRP composite involves manufacturing of fiber preforms and then reinforcing these fibers with the matrix material by various techniques. Fiber preforms involve weaving, knitting, braiding, and stitching of fibers in long sheets or mat structure [125,126,127].

How to join FRP sheet : Install the Corner Moulding and Panel

Why is FRP used in fiber cable

FRP rods serve a dual purpose. It provides cable reinforcement during installation, reduces tension on signal carrying optic fiber/ conductor. The lightweight FRP prevents the cable from sagging in aerial installations and its rigidity and strength takes on the load of cable.

Additionally, FRP is nonconductive, with high dielectric capability, and a good insulator with low thermal conductivity. Pound for pound, FRP is often stronger than steel in the lengthwise direction, but it's important to consider the numbers.Do not bond two non-porous substrates together such as FRP, metal, plastic, foam board, sealed concrete, fiberglass face or mold resistant gypsum wallboard or any other non-porous surfaces. For installations bonding two non-porous substrates together use Titebond Advanced Polymer Panel Adhesive.

Does FRP crack easily : FRPs are brittle, so cracks usually appear in the area where stress is concentrated, such as bolt holes and corner joints of the profile.