As an easy-to-follow comparison, FRP is stronger and more durable than steel – a material we'd traditionally have used to strengthen and reinforce concrete structures in applications such as `steel jacketing`.2. FRP composite materials

Property

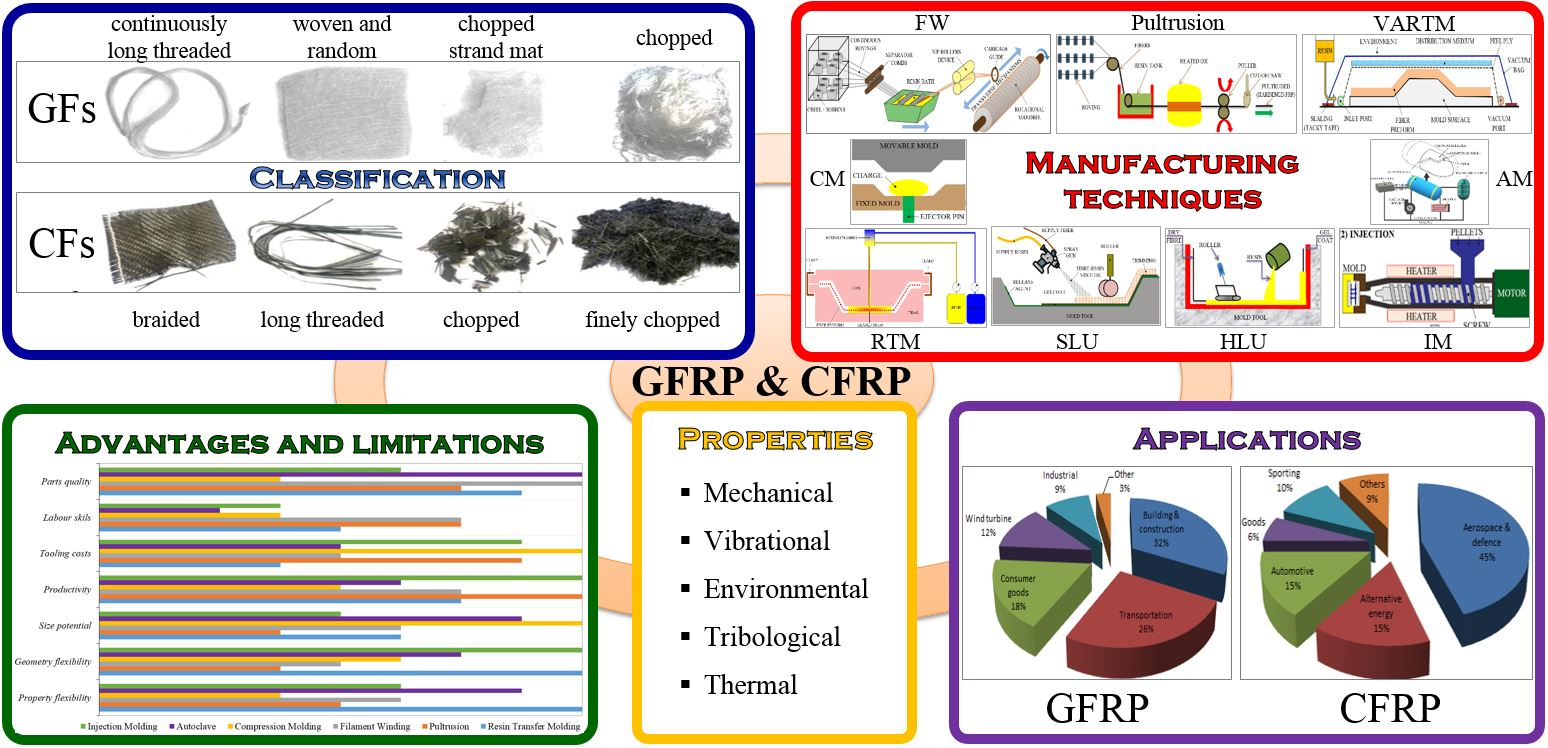

Material Type

CFRP

BFRP

Tensile Strength (MPa)

600–3920

600–1500

Young's Modulus (GPa)

37–784

50–65

Elongation (%)

0.5–1.8

1.2–2.6

Low modulus of elasticity. The modulus of elasticity of FRP is twice as large as that of wood, but 10 times smaller than that of steel (E=2.1*106). Therefore, it often feels insufficient rigidity and easy to deform in product structure.

What is the durability of fiber reinforced concrete : The durability of FRC with steel and macro-synthetic fibers was examined in pre-cracked specimens exposed to the coastal and inland environments for a duration ranges from 7 to 24 months [66]. It was found that the synthetic fibers themselves have excellent durability in both inland and coastal environment.

How long does FRP last

20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years.

Is FRP sun resistant : Firstly, UV resistant FRP withstands prolonged exposure to sunlight without significant degradation, ensuring the structural integrity and longevity of the infrastructure. This reduces the need for frequent repairs and maintenance, resulting in cost savings over the lifespan of the structure.

Additionally, FRP is nonconductive, with high dielectric capability, and a good insulator with low thermal conductivity. Pound for pound, FRP is often stronger than steel in the lengthwise direction, but it's important to consider the numbers. Some of the main disadvantages of GRP include: – Brittleness: GRP can be brittle and prone to cracking or breaking under sudden impact. This can be a concern in applications where the material is exposed to high stress or impact loads.

What are the disadvantages of FRP

Generally, FRP cannot be used at high temperature for a long time. The strength of universal polyester FRP decreases significantly above 50°C, and generally only used below 100℃; Universal epoxy FRP has a significant decrease in strength above 60℃.Fibres aren't a replacement for steel in structural concrete but are very helpful in preventing small cracks caused by shrinkage.What are the disadvantages of using fiber-reinforced concrete

Must be mixed carefully. The fibers used in fiber-reinforced concrete must be dispersed meticulously and uniform throughout the concrete mix.

Cost. Compared to non-reinforced concrete, fiber-reinforced concrete is more expensive.

Weight.

FRP products need little time for production and installation, without compromising durability or function. Highly impact resistant and won't break under impact as traditional materials might. You can get better performance with fewer materials.

Does FRP crack easily : FRPs are brittle, so cracks usually appear in the area where stress is concentrated, such as bolt holes and corner joints of the profile.

How long will FRP last : 20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years. When it comes to structural building materials that last, streel has long held a position at the top of the industry.

Is GRP as strong as steel

The fact is that for safe, robust and cost effective handrails, walkways and pedestrian access, GRP composite products outperform steel and other traditional products hands down. Unlike other materials that may deteriorate, GRP products are designed to be durable regardless of the environment they are installed in. The unique properties of GRP mean that the condition of the product hardly deteriorates when exposed to the elements.The disadvantages of using GFRC are that it can be costly to use. It is always more expensive than using regular concrete. You also have to pre-fabricate GFRC, so a lot of planning is necessary. There is also a chance that GFRC will lose some strength over time, which may make it a poor choice in some settings.

What are the problems with fiber reinforced concrete : What the fiber is made of, its shape, even its color, can lend itself to a variety of pain sources. Whether it's steel, polypropylene, polyester, nylon, cellulose, or even natural, fiber makeup determines whether it has issues with corrosion, absorption, safety in use, adding air to the concrete.

Antwort How durable is fiber reinforced plastic? Weitere Antworten – Is fiber reinforced plastic durable

As an easy-to-follow comparison, FRP is stronger and more durable than steel – a material we'd traditionally have used to strengthen and reinforce concrete structures in applications such as `steel jacketing`.2. FRP composite materials

Low modulus of elasticity. The modulus of elasticity of FRP is twice as large as that of wood, but 10 times smaller than that of steel (E=2.1*106). Therefore, it often feels insufficient rigidity and easy to deform in product structure.

What is the durability of fiber reinforced concrete : The durability of FRC with steel and macro-synthetic fibers was examined in pre-cracked specimens exposed to the coastal and inland environments for a duration ranges from 7 to 24 months [66]. It was found that the synthetic fibers themselves have excellent durability in both inland and coastal environment.

How long does FRP last

20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years.

Is FRP sun resistant : Firstly, UV resistant FRP withstands prolonged exposure to sunlight without significant degradation, ensuring the structural integrity and longevity of the infrastructure. This reduces the need for frequent repairs and maintenance, resulting in cost savings over the lifespan of the structure.

Additionally, FRP is nonconductive, with high dielectric capability, and a good insulator with low thermal conductivity. Pound for pound, FRP is often stronger than steel in the lengthwise direction, but it's important to consider the numbers.

Some of the main disadvantages of GRP include: – Brittleness: GRP can be brittle and prone to cracking or breaking under sudden impact. This can be a concern in applications where the material is exposed to high stress or impact loads.

What are the disadvantages of FRP

Generally, FRP cannot be used at high temperature for a long time. The strength of universal polyester FRP decreases significantly above 50°C, and generally only used below 100℃; Universal epoxy FRP has a significant decrease in strength above 60℃.Fibres aren't a replacement for steel in structural concrete but are very helpful in preventing small cracks caused by shrinkage.What are the disadvantages of using fiber-reinforced concrete

FRP products need little time for production and installation, without compromising durability or function. Highly impact resistant and won't break under impact as traditional materials might. You can get better performance with fewer materials.

Does FRP crack easily : FRPs are brittle, so cracks usually appear in the area where stress is concentrated, such as bolt holes and corner joints of the profile.

How long will FRP last : 20-25 years

A: FRP can last a very long time due to its corrosion resistance and UV stability. So, one can expect FRP products to last at least 20-25 years. When it comes to structural building materials that last, streel has long held a position at the top of the industry.

Is GRP as strong as steel

The fact is that for safe, robust and cost effective handrails, walkways and pedestrian access, GRP composite products outperform steel and other traditional products hands down.

Unlike other materials that may deteriorate, GRP products are designed to be durable regardless of the environment they are installed in. The unique properties of GRP mean that the condition of the product hardly deteriorates when exposed to the elements.The disadvantages of using GFRC are that it can be costly to use. It is always more expensive than using regular concrete. You also have to pre-fabricate GFRC, so a lot of planning is necessary. There is also a chance that GFRC will lose some strength over time, which may make it a poor choice in some settings.

What are the problems with fiber reinforced concrete : What the fiber is made of, its shape, even its color, can lend itself to a variety of pain sources. Whether it's steel, polypropylene, polyester, nylon, cellulose, or even natural, fiber makeup determines whether it has issues with corrosion, absorption, safety in use, adding air to the concrete.