In FRP fabric systems (sheets), the polymer resin (usually epoxy resin) is utilized as a primer, putty coat, and saturant in externally bonded applications. To serve as an adhesive between the FRP system and the concrete surface, the resin is primed onto the surface of the element.FRP strengthening solutions are engineered, specified and installed to solve a host of structural deficiencies or demands in existing structures:

Durability problems due to poor or inappropriate construction materials.

Inadequate design or construction.

Increased loading requirements due to code or use changes.

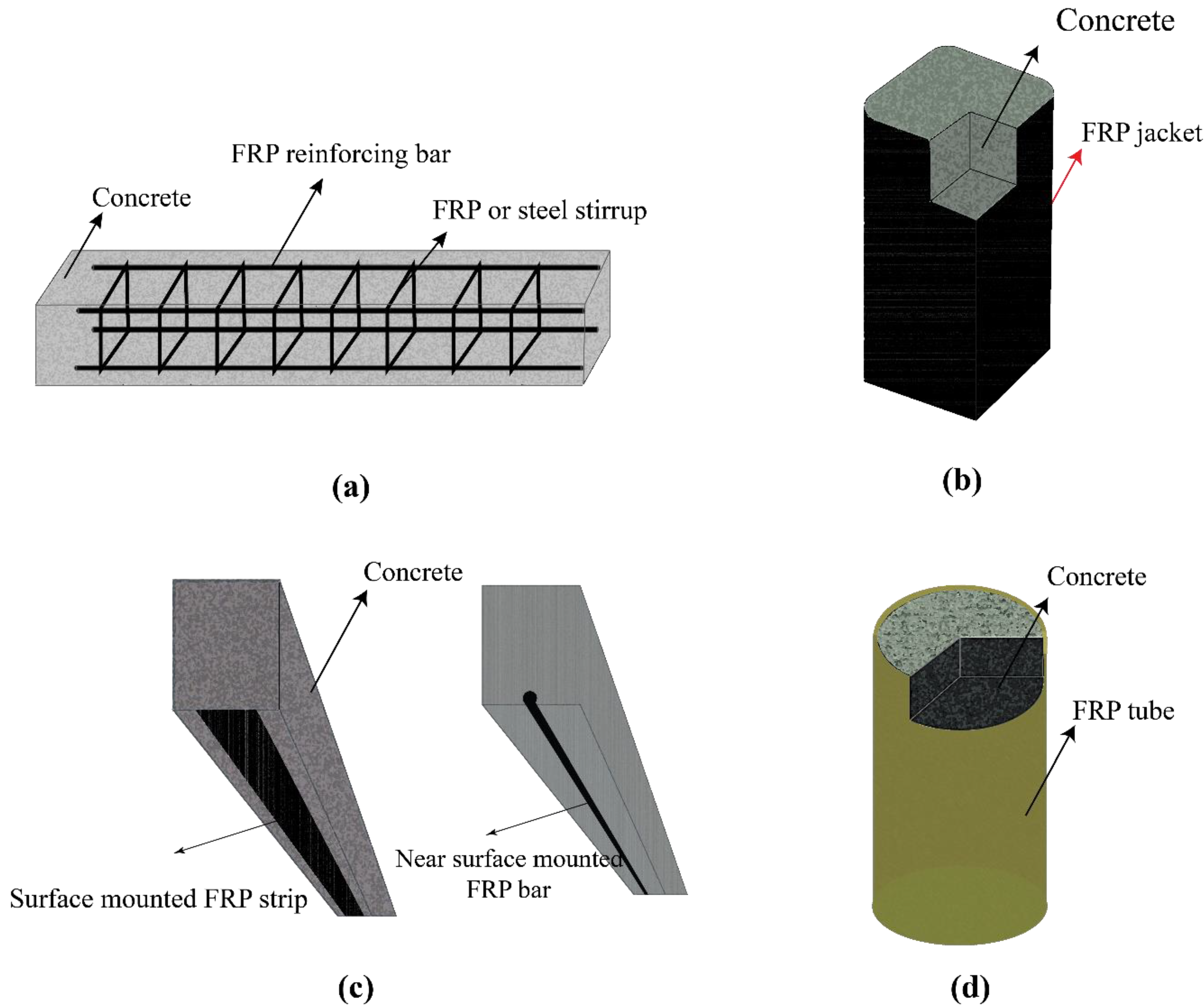

FRP systems used for strengthening of reinforced concrete structures mainly consist of two different methods; the externally bonded laminates and near-surface mounted bars. These systems may contain either carbon fiber (CFRP) or glass fiber (GFRP) reinforced polymers.

What is FRP reinforcement : FRPs (Fiber Reinforced Polymers) are composite materials made of a polymer reinforced with fibers. The polymer is usually an epoxy, vinylester or polyester thermosetting plastic that is combined with a fiber, such as glass or carbon, in order to make the polymer strong and stiff.

What are the benefits of FRP concrete

FRP is known for being lightweight. In fact, it's about eight times lighter than reinforced concrete — meaning FRP is also less labor-intensive to use and install, and requires less equipment. This material also requires less labor during removal processes.

Why polypropylene fiber is used in concrete : Their main role is to overcome plastic shrinkage and limit the formation of cracks in the concrete. As a result, they increase the durability and prolong the life of the element. Micro PPF can be an alternative to crack control meshes. They can be classified as a monofilament or fibrillated.

FRP allows the alignment of the glass fibres of thermoplastics to suit specific design programs. Specifying the orientation of reinforcing fibres can increase the strength and resistance to deformation of the polymer. Fiberglass-reinforced polymer is a strong, lightweight building material that resists corrosion. FRP is sometimes called composite because it's made of a combination of materials that work together for even stronger performance.

What is the FRP process

The Family Reunification Parole (FRP) process provides a specific avenue for U.S. citizens and lawful permanent residents to bring their eligible family members into the United States. However, this opportunity is available by invitation only and under particular conditions.Poor long-term temperature resistance. FRP cannot be used under high temperature for a long time, the strength of polyester FRP decreases obviously when it is above 50℃, and it is generally only used under 100℃. The strength of epoxy FRP decreases obviously above 60℃.Fiberglass-reinforced polymer is a strong, lightweight building material that resists corrosion. FRP is sometimes called composite because it's made of a combination of materials that work together for even stronger performance. FRP's non-slip, durable surface makes it an ideal material for building safer access platforms, catwalks, stairs and railings. Pedestrian bridge decking. FRP can be designed with a non-slip texture making it well-suited for pedestrian bridges.

What are the disadvantages of FRP : The disadvantages of FRP

Low modulus of elasticity. The modulus of elasticity of FRP is twice as large as that of wood, but 10 times smaller than that of steel (E=2.1*106).

The long-term temperature resistance is poor.

Aging phenomenon.

Low interlaminar shear strength.

What is FRP advantages and disadvantages : Advantages: FRP-reinforced concrete structures have high strength, durability, and corrosion resistance. Disadvantages: FRP may lose strength and stiffness at high temperatures, especially when approaching the glass transition temperature of the resin.

How does fiber work in concrete

Synthetic fibers are used in small amounts (approximately 0.1% by volume of concrete) to reduce plastic shrinkage cracking. Synthetic and metal fibers are used in larger amounts (0.3% or more by volume) to improve flexural strength and toughness, and to control the crack width in hardened concrete (ACI 544.1R). Fiber mesh reinforcement significantly improves the flexural strength of concrete, which is essential for driveways that endure heavy vehicle loads and surface movement (like frost heaving). By adding macrofibers to the concrete mix, fiber reinforcement prevents cracking and enhances overall durability.FRPs are brittle, so cracks usually appear in the area where stress is concentrated, such as bolt holes and corner joints of the profile.

Does FRP break easily : FRP products need little time for production and installation, without compromising durability or function. Highly impact resistant and won't break under impact as traditional materials might. You can get better performance with fewer materials.

Antwort How does FRP work concrete? Weitere Antworten – How is FRP used in concrete

In FRP fabric systems (sheets), the polymer resin (usually epoxy resin) is utilized as a primer, putty coat, and saturant in externally bonded applications. To serve as an adhesive between the FRP system and the concrete surface, the resin is primed onto the surface of the element.FRP strengthening solutions are engineered, specified and installed to solve a host of structural deficiencies or demands in existing structures:

FRP systems used for strengthening of reinforced concrete structures mainly consist of two different methods; the externally bonded laminates and near-surface mounted bars. These systems may contain either carbon fiber (CFRP) or glass fiber (GFRP) reinforced polymers.

What is FRP reinforcement : FRPs (Fiber Reinforced Polymers) are composite materials made of a polymer reinforced with fibers. The polymer is usually an epoxy, vinylester or polyester thermosetting plastic that is combined with a fiber, such as glass or carbon, in order to make the polymer strong and stiff.

What are the benefits of FRP concrete

FRP is known for being lightweight. In fact, it's about eight times lighter than reinforced concrete — meaning FRP is also less labor-intensive to use and install, and requires less equipment. This material also requires less labor during removal processes.

Why polypropylene fiber is used in concrete : Their main role is to overcome plastic shrinkage and limit the formation of cracks in the concrete. As a result, they increase the durability and prolong the life of the element. Micro PPF can be an alternative to crack control meshes. They can be classified as a monofilament or fibrillated.

FRP allows the alignment of the glass fibres of thermoplastics to suit specific design programs. Specifying the orientation of reinforcing fibres can increase the strength and resistance to deformation of the polymer.

Fiberglass-reinforced polymer is a strong, lightweight building material that resists corrosion. FRP is sometimes called composite because it's made of a combination of materials that work together for even stronger performance.

What is the FRP process

The Family Reunification Parole (FRP) process provides a specific avenue for U.S. citizens and lawful permanent residents to bring their eligible family members into the United States. However, this opportunity is available by invitation only and under particular conditions.Poor long-term temperature resistance. FRP cannot be used under high temperature for a long time, the strength of polyester FRP decreases obviously when it is above 50℃, and it is generally only used under 100℃. The strength of epoxy FRP decreases obviously above 60℃.Fiberglass-reinforced polymer is a strong, lightweight building material that resists corrosion. FRP is sometimes called composite because it's made of a combination of materials that work together for even stronger performance.

FRP's non-slip, durable surface makes it an ideal material for building safer access platforms, catwalks, stairs and railings. Pedestrian bridge decking. FRP can be designed with a non-slip texture making it well-suited for pedestrian bridges.

What are the disadvantages of FRP : The disadvantages of FRP

What is FRP advantages and disadvantages : Advantages: FRP-reinforced concrete structures have high strength, durability, and corrosion resistance. Disadvantages: FRP may lose strength and stiffness at high temperatures, especially when approaching the glass transition temperature of the resin.

How does fiber work in concrete

Synthetic fibers are used in small amounts (approximately 0.1% by volume of concrete) to reduce plastic shrinkage cracking. Synthetic and metal fibers are used in larger amounts (0.3% or more by volume) to improve flexural strength and toughness, and to control the crack width in hardened concrete (ACI 544.1R).

Fiber mesh reinforcement significantly improves the flexural strength of concrete, which is essential for driveways that endure heavy vehicle loads and surface movement (like frost heaving). By adding macrofibers to the concrete mix, fiber reinforcement prevents cracking and enhances overall durability.FRPs are brittle, so cracks usually appear in the area where stress is concentrated, such as bolt holes and corner joints of the profile.

Does FRP break easily : FRP products need little time for production and installation, without compromising durability or function. Highly impact resistant and won't break under impact as traditional materials might. You can get better performance with fewer materials.